-

Posts

1,016 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Store

Events

Posts posted by Gary Flinn

-

-

Try another Battery?

-

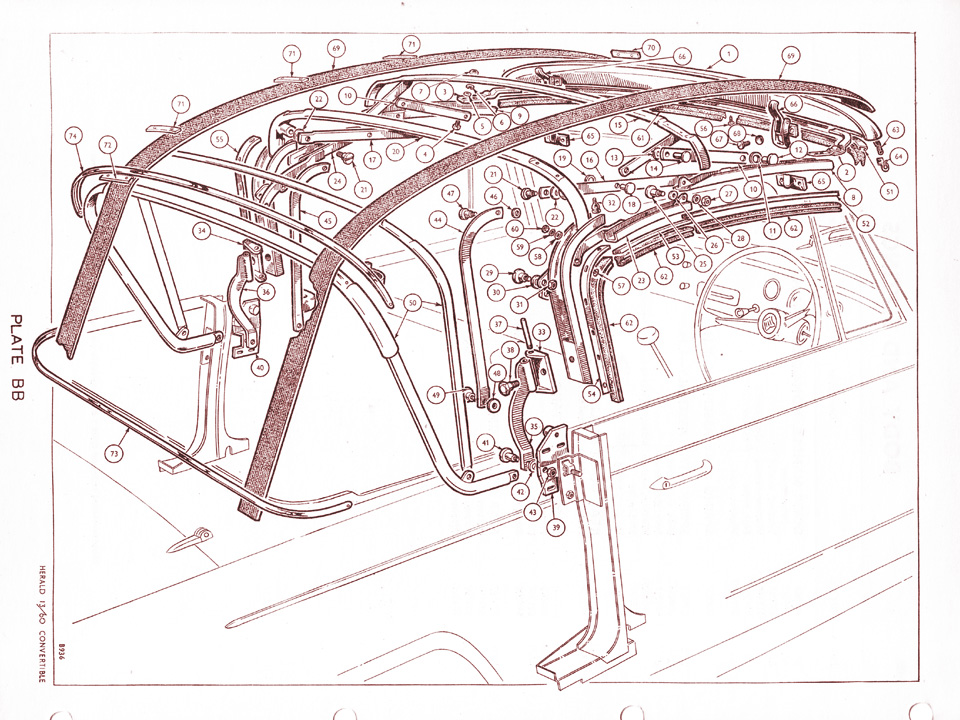

Be aware that the part of the Header rail that bolts onto the side of the main hood rail was originally fixed with a large Rivet/Pin.

This was supposed to give a bit of side to side movement when the hood is up and the car flexes, this pin gets seized up with rust over time (SEE ITEM 2 ON ATTACHMENT) and this is what causes the break between the header rail and bracket.

A bit hard to explain, but hopefully the diagram shows the pin, there must be a bit of horizontal side to side movement on this large rivet/pin or it will break again eventually!

I had to free off both sides on my hood frame during my Vitesse's rebuild

-

With that pedigree the selling price should exceed the estimates

Yes, reckon it will go for £10K Plus, but you never know for sure at Auctions?

-

Very tempted, 27K Miles only and mostly original, I've long admired this car?

Wish I had a bigger Garage

-

Did you have any of the Spacers fitted that set the Pre-load/End float on the bearings?

With the Rotoflex set up it's vital this is set correctly or you are likely to ruin the wheel bearings

The Canley Classsics Website tells you how to set up the Endfloat correctly if you fit new bearings or if you want to check the existing is correct.

Shims are available now too I believe?

-

Although not as good as the Prestige or Revington conversions, whats wrong with New Superflex Bushes and one of the Moss Linkage kits to the original set up?

It will be cheaper for sure!

Just fitted these on my TR and am happy with the set up, all for around £50?

-

They are banded, not sure I would trust them.

Regards

Paul

Me Neither

, Original ones would be better?

, Original ones would be better? -

The nylon certainly looks of poor quality. It's gone brittle as if it has been left out in the sun for a couple of years and the pressure of the spring has eventually pushed through the material. I hope the next one lasts a bit longer because I for one find the whole rigmarole of getting the transmission tunnel in and out for such a daft little job to be a right chore.

Wayne

I know what you mean about the Tunnel removal, it's a right pain in the A**E!

A Scottish guy on the Vitesse Facebook forum made up a removable top portion of the Tunnel to save undoing all the self tappers and ease access to the remote mechanism?

Seems like an excellent idea to me.

-

I Have had similar problems with my old Vitesse and fitted 3 of these Kits between getting it back on the Road in 2006 and selling it in 2015?

During this time the first one fitted during the Restoration lasted around 10,000 Miles, the last two around 1,000 miles each!

There is obviously a problem with the grade of the main Nylon Ball, this was the item that failed every time on my car allowing the Springs to poke through and the lever to go all loose.

I did as suggested by Pete make sure the Spherical cover was smooth, this didn't make any difference I'm afraid.

-

I don't believe the Original Pumps are repairable, as far as I know Repro ones aren't available either

A good secondhand one if you want to stay original is the way to go, IF you

can find one that is?

-

Yes looking forward to it, will be there in the TR all being well

-

I have Vitesse 2 litre MK 2 with a noisy diff., there is some noise whilst driving but trouble

is most apparent when moving away slowly or reversing.

I happen to have a diff which came out of a 2 litre Mk 1, does anyone know whether this

would be a direct replacement ? I know that the ratio is the same, but I read somewhere

that the Mk 2 has a stronger spring and I wonder whether there is a difference in the studs

securing spring to diff.

I have changed diffs on a non rotoflex car before which was quite easy, I wonder just how

difficult the Mk 2 will be. I know that a special tool is required to deal with the spring.

Any advice please?

Jeff.

Jeff

The Mk1 Diff will be a straight Swop, the Mk2 Vitesse does have a different profile spring but still bolts to the diff with the same 6 Studs as all Heralds & Vitesse's?

A spring lifting tool will be needed on the Mk2 with the Rotoflex suspension, have a read of a Workshop manual regarding the Diff swop.

Regards

Gary

-

Just for info the the TR5/Early TR6 Trims are actually 16 and 3/8" total diameter although the wheels are for 15" diameter tyres.

I would guess the GT6/Vitesse/PI trims are around 14 and 3/8" diameter total

Gary

-

I have retained the original wheels and hubcaps on my otherwise much-modified Vitesse. For me, the fake Ro-Syles typify a particular range of Triumphs in the late sixties/early seventies. I realise that there are benefits of alloys but I am sticking to the original hubcaps.

Tom

I couldn't agree more Tom, just converted my TR5 back to Rostyles, love the look of em, just need to make sure they don't go flying off into the distance!

-

Steve

I've had a look down the List and there's a few I know of local to me in Derbyshire, the Light Car Co on Derwent Street was a Kenning garage up to the Early 90's, I remember getting Service parts for my Stag from there. Also I remember LMA Motors in Godfrey Street Heanor, in the mid 1980's it was a privately run Garage but they still had some of the Original Sales Posters up on the Wall including the Mk2 Vitesse two Seater beater Poster, wish I'd nipped in and asked em if they wanted to sell it!

Another Garage in Moor Street in Burton-on-Trent is right next to were I work, its a Kia Dealer now but is still the same Layout.

Another one me and my mate John used to use regulaly for parts for our Vitesse's was a Garage called Service Motors in Leabrooks near Alfreton, I remember getting some Original Door Window Weatherstrips from there in the mid 80's for my first Vitesse, sadly this is now a Co-op Supermarket!!

Keep the Info coming, I for one find it fascinating reading

-

Did this replacement on my Vitesse, the hardest job is digging the old seal out, I used an old Screwdriver to lever it out a bit at a time.

There's no need to remove the cross member, undo the Nut and the Flange should pull or tap off easily.

Make sure you fit the Nut back to the same position and use a new Split pin.

Also make sure the drive flange is smooth and rust free where it will rub on the new seal.

The Double lip type seals are worth fitting too, you get twice as much chance of sealing the oil in!

It's worth changing the oil while your at it, but Triumph didn't put a drain plug in most of the Herald/Vitesse diffs, so some sort of suction Pump will be needed with the Diff in the Car ?

-

1

1

-

-

500 Miles seems to ring a bell?

-

The spring should have 11 Leaves if its a MK2 Vitesse Spring?

Dimensions should be around 1012mm Eye to Eye and with the spring removed and resting on the floor in its fitted position if you measure from the underside of the middle of bottom leaf to the floor it should be around 165mm if it's not sagged?

I stripped a Good Mk2 spring down and refurbished it, I cleaned and derusted each leaf, re-painted and re-assembled with new Thrust buttons between the Leaves and new Eye bush's, the car rode much smoother after,

The Rear Diff oil seal is not to difficult to swop after removing the Nut and drive Flange, getting the old one out can be a pain! Check the part of the Propshaft Drive flange that runs on the lip of the seal for rust and pitting, if bad it will need cleaning up with emery paper till smooth, if really bad a New or good Secondhand one will be needed.

Setting the Endfloat on Rotoflex suspension can be tricky, the Canley Classics website helps explains it, but if your planning on a CV Conversion some systems do away with the Shim system?

-

Don't raise the Engine to Much or you may find the Front rocker Cover Stud/Bolt, Rocker cover or even the Front Thermostat housing may catch the bonnet and make a nice dent?

Not!

-

My previously owned June 1970 built 'H' Registered Vitesse was fitted with the Smooth Lens.

I believe they may have changed some time during 1970 from the peak type?

-

It's not Valencia Blue and Looks a bit to Lighter shade for Royal Blue?

It may well be a non-standard colour, looks a bit Metallic to me too.

-

If you undo the Nuts/Studs that hold the Spring to the Diff on a Rotoflex car the Spring will be under tension still and get Wedged under the rear body!

You maybe better removing each side completely but you will need a spring lifting tool.

Any work on the Rotoflex Rear Suspension is normally a Pain In the A**e

Never dealt with Mike Personally but he's got a good reputation and been in to Triumphs for years?

-

Not an expert on the GT6 but if the Sills have a proper jacking point at the rear this would seem the logical place to me if all you have is a Scissor Jack?

On the Herald/Vitesse I always used the corner of the Side rail and rear outrigger, but no Rear outriggers on the GT6.

-

Excellent link John

I still don't fully understand it though

More bed time reading needed!

NEC Classic Car Show

in Other Events

Posted

In total agreement, was considering going myself till I added up all the costs

And the Car Parking charge is another RIP OFF!!!