RogerH

-

Posts

743 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Store

Events

Posts posted by RogerH

-

-

The sad stupidity that Beeching carried has not actually been improved in any Gov't department.

Short sighted jobs worths doing what the master ordered.

Roger

-

1

1

-

-

5 hours ago, Pete Lewis said:

you missed getting a RH &D Loco steaming past in the shot

Pete

Sadly Not running at the moment

Roger

-

-

Triumph drawings missing - Pah

After the last Concorde was built the manufacturing drawings were of little use. In the late 70's early 80's they were sold for a song to an enthusiast.

Not exactly sure what and how many but it was a significant amount of specialist information. Still it wasn't needed anymore.

Until !!!! BA started to lose its rudders oops!!

How do you make new rudders with no drawings. They had to hire the drawings back for 'not' a song. Somebody became quite wealthy overnight.

Roger

-

You can't rub the chrome off as you will get an undulating surface that will need professional polishing before re-plating.

The corrosion pits need to be pickled clean (acid),

Then filled with Copper and polished back.

Then Copper plated & Polished.

Then Nickel plated and polished and finally Chrome.

Why not send them to the UK for Chrome plating.

Roger

-

Hi John,

on the smaller rivnuts M3 & M4 Ali pull them up until you feel it go tight. Then waggle the pliers. If it is in tight there will be no movement.

If you feel any slack then keep squeezing.

Steel and Stainless steel should not pull through.

The biggest problem is trying to pull down M6 stainless. Power pliers are required.

Roger

-

Those women type people are very cunning.

Roger

-

1 hour ago, PeteH said:

HI

Without wishing to "teach granny to suck eggs". Are you absolutely sure the head, or even the block (unlikely, But?) are perfectly flat?. Also, re the leakage, have you considered checking the head, particularly, with NDT, micro cracking is hard to detect visually, but should show under dye penetrant.

Reading what has been written, I don`t think improper Torquing is necessarily the issue. Though the state of the Head gasket would suggest a lack of such?. Which would beg the question, is the torque wrench accurate?. "Back in the day" our`s where re-calibrated on a frequent basis. Another question which niggles, Do the flanged washers need a different torque figure?. Using separate washers, there are two "sliding friction faces" the flanged washer has only one.

Generally speaking, the manufacturers tolerances where usually "sufficient" for purpose, so increasing the torque, as some would, to get a tight joint, would be more likely to over-stress the studs/bolts.

I note also, the use of an NOS Stanpart Gasket. Copper, age hardens so could that be contributory?

Pete

On a composite head gasket the ability of the Copper to compress would be a very minor issue indeed.

The sandwich filling takes up all of the compression when torquing.

Perhaps it becomes more relevant if it was a solid copper gasket.

But then steel gaskets have no compression available.

The washers under the stud nuts are important - they are special and need to be hard.

Roger

-

Hi Chris,

in my little world the 'plug' weld is the preferred alternative. Much more control over what is going on.

The only issue with 'plug' welds is to ensure that the top surface hole has a big enough diameter.

The usual supplied hole punch/Joggler has a 3/16" punch which is way too small. You will often get NO penetraion.

1/4" (6mm) is better but iffy.

5/16" works every time.

Excellent study and pictures that you have posted.

Roger

-

1

1

-

-

Hi Kevin,

for one of my jobs I needed to weld an end plate onto a tube (mild steel)

I got crafty. I fitted the tube (only 2" long) into a small 4 jaw chuck, rigged up the torch in a set position and turned the chuck with string and gears.

After one rotation, job done. It was a revelation.

Doing it by hand would have me tearing my hair out

As mentioned above I shall spend a week this summer doing some serious practice.

Roger

-

Have a look on the R-tech website. They have tutorials for all the metals/thicknesses/and configuration.

Getting a decent weld pool is one thing trying to insert the filler rod into it is another.

I have had some good success joining steel and Aluminium but without the filler rod.

This summer I will have another weeks teach-in and see if I can improve on using the filler rod.

It may be easier to practice on slightly thicker sheet than the normal car thickness Perhaps 2mm

Roger

-

Hi John,

Like Clive I also use Vehicle & Wiring Products. TRy and make a list of what you need for now and possibly down the road as P&P is expensive for a small item.

11amp is their smallest and comes in solid colours

16amp comes in solid and dual colours

RS Comps do much thinner cables

Roger

-

12 minutes ago, Peter Truman said:

You mean a spray can of “Start You Bast**d”

...............that works.................

Roger

-

3 hours ago, RogerH said:

Hi Folks,

does anybody know of a cheap/free drawing package that does dual coloured dashed lines.

Roger

Found it !!!

Using Word. Lay down a dashed line in one colour (eg Red) then lay another dashed line close to the first in the second colour (eg green)

Then lay one line on top of the other (spaced accordingly) - ed/Green line

Roger

-

Hi Folks,

does anybody know of a cheap/free drawing package that does dual coloured dashed lines.

Roger

-

Hi Dave,

sitting quietly for so long ( 2 weeks) may allow the petrol to drain away from the carbs or evaporate.

When you crank it over it is trying to start but with not enough (initially) fuel so the plugs get wet but unable to burn off the excess fuel.

Make sure the battery is well charged,

I would NOT put WD40 inside the dizzy - it isn't designed to dry out the cap but it will leave a residue that may cause tracking/arcing

Put the WD40 in the dustbin and let the binmen take it away.

Roger

-

Hi Roger,

I have one of Marco's (Z320 on the TRR Forum) for my 4A. In these days of liquid gold in the fuel tank it is a nice gadget to have.

Roger

-

1

1

-

-

If it is oil coming down the valve guide then there is a side issue.

The oil will mix with the petrol intake and lower the RON. So if you are using 95 then it may be much lower, 93 perhaps, and bring on pinking.

Also TRy using a hotter spark plug to help keep the plugs clean.

Roger

-

1

1

-

-

Hi Jeff,

I suspect my 'answer' is not the 'the' answer.

#4 is usually the hottest pot - shielded from the rad fan by the other pots.

#4 is also nearest to the rocker oil feed. There may be more oil escaping the rocker assembly and then getting into the inlet valve guide.

#3, 2, 1 is getting less and less oil to them.

Roger

-

Hi Paul,

NOS capacitor (Condensor) is not always the way to go.. Capacitors like to be used regularly.

Another annoying area-On my TR4A 25D dizzy the flexible wire inside that joints the outside world to the points. had become unattached to its tag.

The solder had peeled off the tag.It look good but was not. It took me three r fours days travelling across Scotland before I found it.

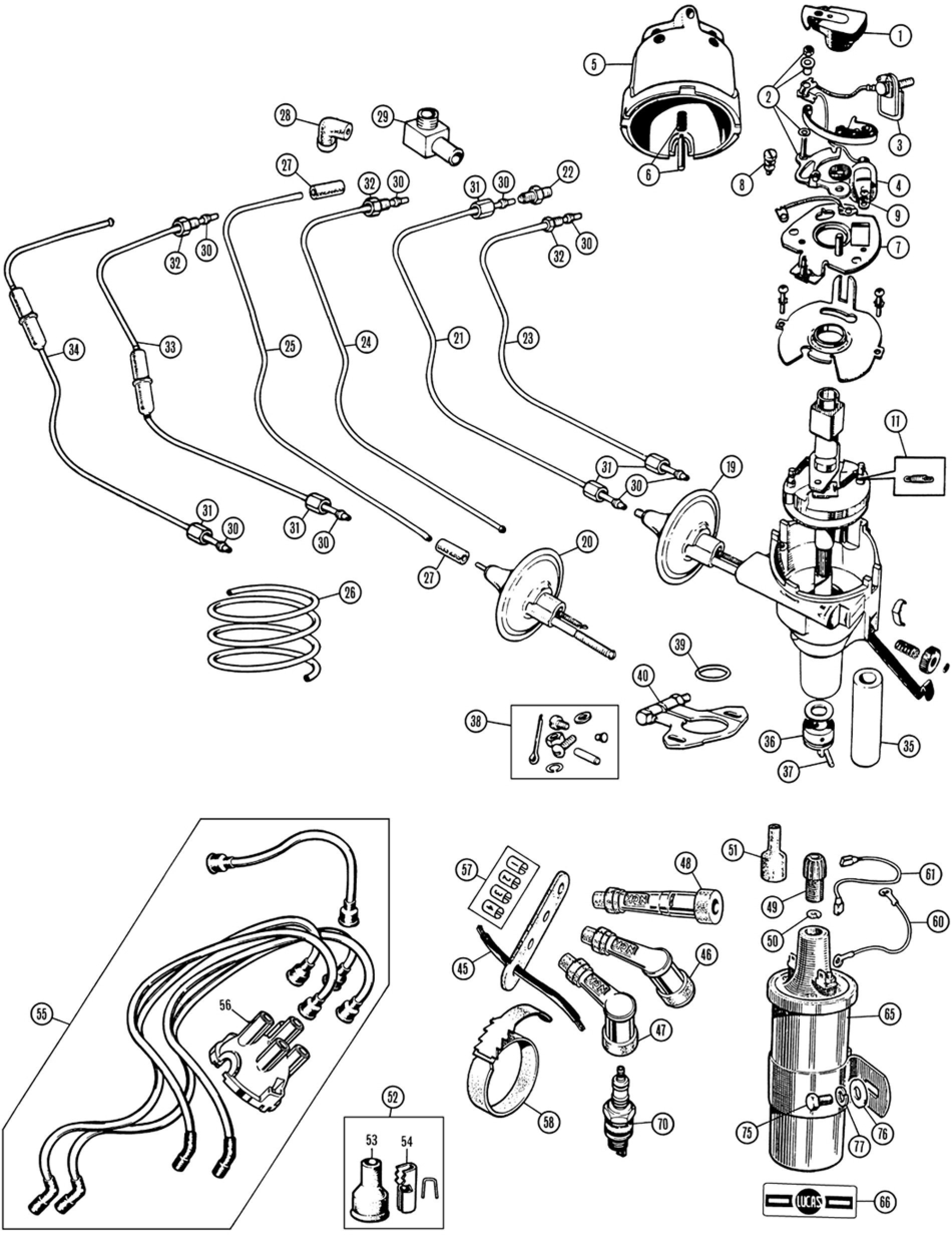

The wire on item 3.

Roger

-

The seam (butt) weld is a good way to go. I think I would have made the cut-out as a circle.

If the corners are not welded properly they may start cracking.

Roger

-

It looks like a Gloria.

Beautiful car.

Roger

-

10 hours ago, Pdv said:

Hi,

I purchased new points, rotor arm, distributor cap and new leads for my, new to me at the time 13/60. It went from starting first time every time to not starting at all. I am restoring another 13/60 at the moment so have been concentrating on that.

Have found the rotor arm and distributor cap and that will at some stage swop those back and see how it goes.

So why did I do that when it was all going well, I am asking myself the same question.

It is not good though to not have the confidence in what you buy.

When changing electrical components do one at a time and make sure it works. Then the next one etc etc.

When buying parts as spares. Fit the new one and see that ot works. Put the old one in the spares box - you know it will work.

Roger

-

2

2

-

-

44 minutes ago, Paul H said:

+++++1

Top quality from Martin Jay the 'Dizzy Doc'

Roger

Drive Your Triumph Day 10 Feb

in Other Events

Posted

At the Pilot Pub in Dungeness I had 'mushy' peas with the fish and it also glows in the dark.

Roger